In recent months outdoor racing has been nought but a pipe dream but that shy old sun has been poking his head out just lately so what better time to treat oneself to a nice new kit to build.

OK if you insist!

Rather than opt for one of the more conventional offerings from the traditional manufacturers I dropped my coin on something a little more eclectic.

Hobao, a Taiwanese company well known for their great 1/8 buggies, have put their design guys to work and come up with a 1/10 touring car, the H4e.

Retailing at a smidge under £300 and boasting a number of features not found on other cars, as well as some that are available as expensive options, this kit appears to be decent value.

I also noticed Atsushi Hara testing one over the winter so it's clearly prompting interest at he highest level.

(Click on any pic for gallery view)

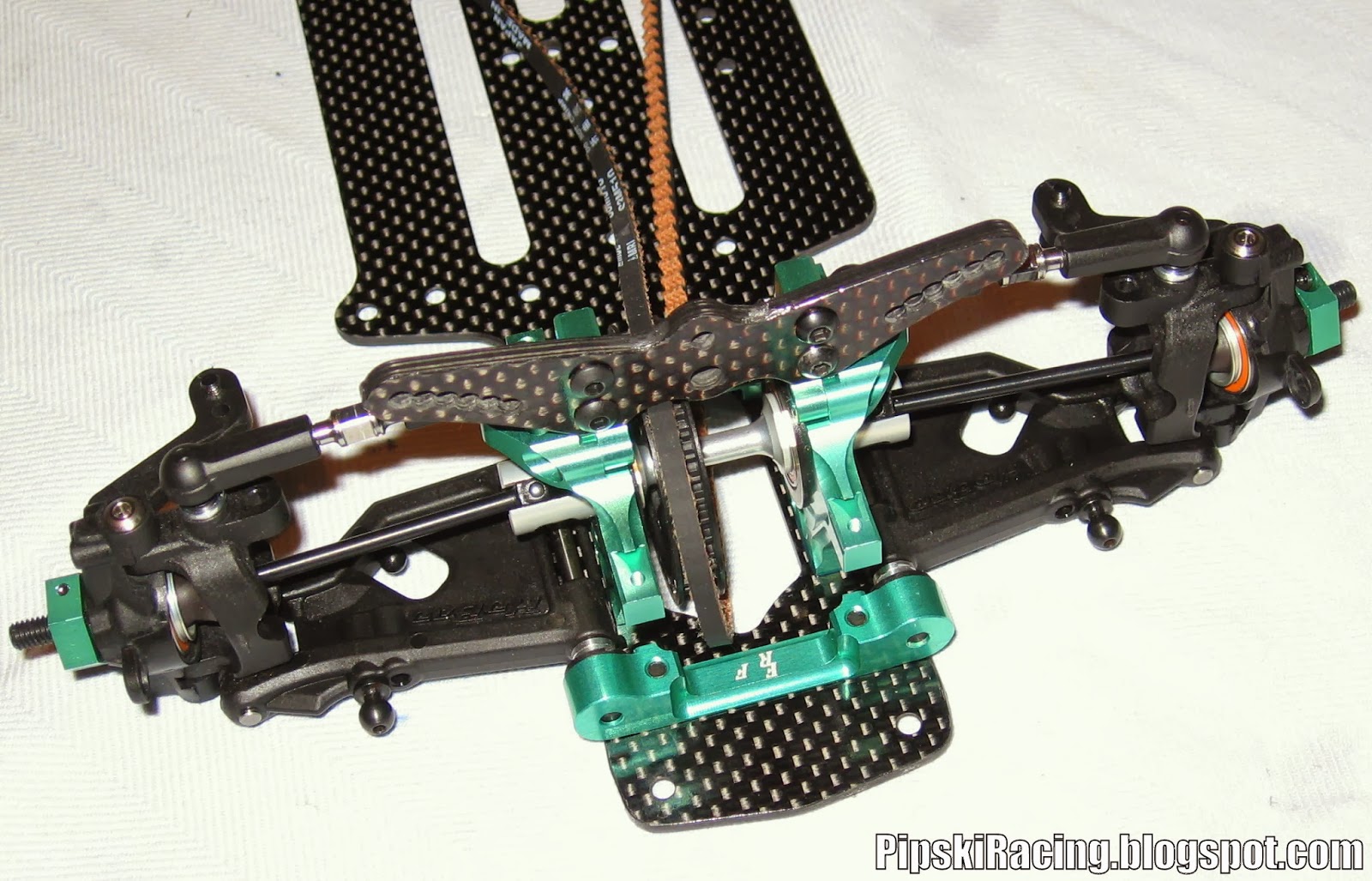

On opening the box one is greeted by the usual assortment of numbered bags full of lots of nice carbon and alloy bling. In their quest to do things differently Hobao have supplied all this nice alloy in green, not to everyone's taste but I like it.

First impressions are that all this alloy and carbon is nicely machined and the plastics look to be well moulded.

Resisting the temptation to rip some bags open and get this build under way was difficult but as always I took the time to carefully seal and polish the edges of all the carbon parts.

This is well worthwhile on the chassis plate as it helps prevent delamination, for the rest of the parts its really an exercise in aesthetics, but I'm a tart so I take the time to do it.

Using a cotton bud I run Cyanoacrylate (super glue) around the edges, cut back with wet n dry (600ish) then repeat and polish with T-cut. The more time and effort you spend on this the better the finish you'll achieve.

Eventually I was able to get the manual out and open a few parts bags.

My manual came with an addendum sheet detailing a few changes, I guess later kits will have these incorporated.

The manual is ok, it doesn't reach the benchmark Xray standard but it does have plenty of clear black and white diagrams that the experienced builder can comfortably follow.

The innovations begin straight away in Bag A.

The alloy bodied shocks are mega big bore short travel items.

Hobao claim that, because of the large bore, these shocks work effectively with a much lighter oil than would normally be used. I fitted them with the 3 hole pistons (2 hole are also supplied) and filled them with AE20w oil.

The supplied springs are rated as 'medium' I invested in the the Hobao optional 'soft' and 'hard' springs as I know of no others that will fit.

With the shocks built and put to one side I moved on to the diffs.

Almost all touring cars currently available come with a front spool and rear gear diff, the green machine is no exception.

The spool bolts together nicely.

The kit outdrives are alloy, steel parts are available from the options list.

The kit outdrives are alloy, steel parts are available from the options list.

When building the rear gear diff there are a couple of areas that warrant extra care. Firstly pay attention to the shimming, mine was quite tight with the kit shims so I ended up re-shimming to loosen it up a little.

Second, when joining the case halves ensure the large sealing o-ring is properly seated to guarantee a smooth leak free unit.

Fill to the cross shafts with 1000wt oil.

No leaks .. Yay!

Given Hobaos background it's no surprise to find that the c-hub arrangement owes more to 1/8 buggy design than current touring car thinking, we'll see how it works on track soon enough.

A couple of points of note in these bags are the alloy hexes and double cardan joint (DCJ) driveshafts both big buck options on other well known brands.

DCJ driveshafts provide more and smoother steering lock

The DCJs come pre-built but it's worth giving them a once over. I applied a little black grease and then used a little heat shrink around the assembly.

The arms look like sturdy fellas.

Time to start bolting some of this green goodness to the chassis.

I use a blue thread lock on all steel into alloy screws, this prevents screws loosening in use whilst at the same time preventing corrosion and allowing easy removal when necessary.

A nice feature here is that the upper half of the bulkhead is hinged to the bottom half, thus ensuring diff maintenance is a doddle.

Decent heavy duty belts come as standard.

The hinge pins run in nylon inserts, kick up is adjustable using the supplied shims under the pivot blocks.

Another handy little feature is the holes in the ball cups allowing access to the pivot ball without popping the cup, causing unnecessary wear and tear.

Coming together nicely.

With the shocks mounted to the front end I'm starting to get a feel for what the finished car is going to look like, pretty good methinks.

So far I am enjoying this car, it's nice to build something that seems to pull together some of the best features of its competitors whilst at the same time managing to be a little different.

That's it for now, time for a cold one, I'll be back in the man cave soon to find out what else Hobao has in store for me.

Check back in a couple of days for Part 2.

Hi, just a quick tip with fitting the o-ring in the gear differential. In the groove where the o-ring sits, use a needle shaped file and lightly score a groove all the way round it's diameter creating a slightly larger indentation. Put the rubber o-ring in very hot water and leave for 10 minutes before taking it out and drying it (the heat slightly expands the rubber making it easier to fit). Fit the rubber o-ring and it should stay in place!

ReplyDelete